Here are a selection of articles written by Dr M K Vasant, which were published in professional dental journals.

Dr Manny Vasant MBE

BDS MGDS RCS (Eng) MGDS RCS(Ed) FFGDP(UK) FDS RCS(Ed) Specialist in Prosthodontics

Dr Sandip Popat

BDS (Lond) LDS RCS (Eng) FDS RCPS (Glasg)

MClinDent (prosthodontics) MRD RCS (Eng)

Specialist in Prosthodontics

Dentists today have a plethora of porcelain systems to choose from. New systems are being introduced all the time and the discerning practitioner should be able to make an informed choice in conjunction with his/her dental technician.

This article aims to discuss the concept behind the available porcelain systems very simply, by dividing extracoronal restorations into the core material (which has a high degree of variation amongst the systems available), and the surface or veneer (which varies little between the systems). It aims to explain the chemical composition of the material in question since many of the systems available on the market today are merely slight variations of one another. These differences, however, may influence their suitability in a particular clinical situation.

An understanding of these subtle differences will improve the clinical care and may impact upon the cost of a given restoration, both biological and financial!

It should therefore form a part of clinical governance. Needless to say, the choice should also be based on the degree of technical support available locally.

Core, surface layer, porcelains, feldspathic porcelains, leucite, low fusing ceramics.

In essence a full coronal tooth - coloured restoration is composed of a sub-structure, or 'core', and a surface layer or veneer. In a given restoration, an attempt is made to mimic the function and appearance of dentine in the 'core', and the function and appearance of enamel in the surface layer. Of all the available restorative materials, porcelain has over the years led the way in mimicking natural tooth aesthetics, albeit with considerable limitations.

Porcelain is a specific type of ceramic. It is made up of white clay (kaolin), quartz and feldspar. The ingredients are pulverised, blended, shaped and finally baked. It is essentially the same material as "white ware" used in industry for the construction of tiles, sanitary ware etc. Historically, Pierre Fauchard was credited with recognising the potential of porcelain enamels and initiating research into porcelains in order to imitate the colour of teeth and gingivae.1

In the 1950s and 1960s great improvements were made in the strength of porcelain, following the addition of alumina. These became known as Aluminous Porcelains. Much early work on prefritting alumina-glass composites was described by John McLean. However, whilst the addition of aluminium oxide increased the strength, the presence of this second phase reduced the translucency of the porcelains, and thus reduced the aesthetics. This therefore limits the use of the alumina-reinforcement to the construction of the internal core to support the more translucent feldspathic porcelain.

The introduction of vacuum-fired porcelains in the 1960's led to a great improvement in the aesthetics due to the reduction in internal porosity. Much of the research and developments over the next 20 years or so were directed at improving the strength and marginal integrity.

Leucite Reinforcement (Figure 1)

In the 1950's the addition of leucite (crystals of a potash-alumina-silica complex) increased the strength of porcelain further by limiting crack propagation. Unfortunately, the leucite increases the potential for wear of opposing teeth and also reduces opalescence. The proportion of the crystals varies with each system and to counteract the reduction in opalescence with the increased leucite content, blue pigments are added to the system. A new wave of ceramics has appeared since the 1980s aiming to further improve the aesthetics and address one of the most important drawbacks of porcelains - the potential for catastrophic failure.

The increase in coefficient of thermal expansion also enabled these porcelains to be fused to certain gold alloys to form complete crowns and metal ceramic bridges.

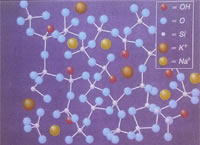

Illustration of a "self-healing" effect of hydrothermal ceramic due to the build up of Si-OH layer on the surface which seals micro flaws continuously.

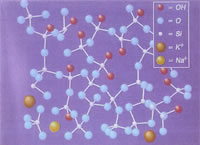

This surface structure of regular dental ceramics before and after hydrolytic testing showing increased surface flaws. (Figures 2 and 3 reproduced from DUCERA dental GmhH page 20)

Ionic exchange strengthening (ion stuffing) is a process that creates a layer of surface compressive stress by exchanging the smaller glass modifying ions with large ones. During this process, the smaller sodium ions are replaced with larger potassium ions. Potassium ions are squeezed into the spaces formerly occupied by sodium ions. The larger ions enter the glass or porcelain by diffusional exchange at an elevated temperature from a molten salt bath. These larger ions produce atomic crowding thus surface compression. Modification of surface chemistry also causes a reduction in thermal contraction,

Commercially available pastes such as Ceramicoat and Tuffcoat have eliminated the use of hazardous salt baths and simplified the process.

These porcelains have hydro thermally introduced OH-groups and fuse at lower temperatures hence called low fusing ceramics (LFC) (Figures 2 and 3). As explained conventional porcelains contain surface micro flaws or develop them after exposure to the oral environment. These flaws can increase over a periods of time, resulting in surface discolorations and flexural strength reduction. In contrast, it is claimed that hydrothermal porcelain (which are low fusing Ceramics) have a potential for "self healing" and are more resistant to fracture due to their continuing ability to form the hydrolytic layer (Si-OH) in the mouth! 2,3,4

This increase in strength results from a surface layer with many OH-groups, built through alkali and hydroxyl exchange. The surface layer is thus more flexible and is claimed to "heal" surface flaws.

Thermal tempering has also been explored to strengthen dental porcelains. This extends much deeper than surface chemical treatments, but controlling cooling rates for complex objects such as crowns makes it impractical

Despite all the latest developments to improve strength, most porcelain systems rely on the conventional feldspathic porcelains to reproduce the outer surface for good aesthetics. For the purposes of this article, it is convenient to discuss the core materials and the surface layer materials separately.

A veneer of surface feldspathic porcelain is bonded to a core. As discussed, feldspathic porcelain is a very brital material. The use of a 'stronger' core will help minimise catastrophic failure.

Bonding to dentine has been shown to increase the strength of the porcelains.5 Effectively, natural dentine core is used as the inner core to which feldspathic porcelain is bonded instead of artificial substitutes. This enables the operator to prepare the tooth more conservatively as no space is required for a synthetic core (Figures 4,5,6,7).

In-vitro testing of natural teeth restored with dentine-bonded crowns has yielded fracture strengths similar to those of intact teeth.5 In a retrospective study of 25 posterior inlays, a much higher failure rate was noted when light cured resin, rather than dual cured resincements were used.6

This is the most commonly used method in clinical practice whereby feldspathic porcelain is bonded onto a cast metal framework. For production of multiple units, this is still the most reliable choice.7 The metal ceramic crown remains the workhorse in restorative dentistry and has rightfully earned the nickname of-" a dental brick".

A metal framework may be chosen from precious, semi-precious or non-precious alloys. Each has its advantages. The mechanism of bonding is facilitated by matched thermal expansions of the two materials, Van der Waal forces and a chemical union between various metallic oxides. Despite the advent of other systems described, the strength, longevity and performance of this material is undisputed. The grey metal base however, affects the light transmission through

More recently yellow alloys have been introduced which are capable of bonding to hydrothermal bonding ceramic eg Duceragold. The ceramic used here is claimed to have better opposing tooth wear properties due to reduced size of leucite crystals and more homogeneous material structure which is more transparent. Furthermore it is claimed that "healing" hydroxyl layer in the mouth leads to strength increase e.g Duceram LFC (low fusing ceramic) discussed later on.

The yellow gold provides a better colour match in certain situations, particularly where yellow (Vita A and B) shades are to be reproduced. The yellow gold also seems to have more acceptable appearance against gingival tissues.

These techniques are an alternative to the traditional

The McLean Sced Crown involves the use of twin platinum foils in the construction of the crown using the conventional Aluminous Jacket Crown technique. The inner platinum matrix, which eventually forms part of the crown, is tin plated and oxidised to facilitate bonding to the porcelain. This procedure appears to eliminate open surface defects from which tensile failures may originate. Minassian (1978) tested porcelain crowns using the twinfoil platinum bonded technique and found that there was a statistically significant increase in the fracture strength from 184N for standard aluminous porcelain crowns to 286N for the bonded platinum crowns.15

The second technique is similar but the grey platinum foil is replaced with gold (Captek System, Shottlander). This involves the adaptation of a wax strip impregnated with gold-platinum-palladium powdered alloy, on to a refractory die. Firing produces a rigid porous layer, which then is in-filled with gold from a second wax strip by capillary action. This is then veneered with porcelain. It is claimed that this improves marginal fit, gives better aesthetics and better biocompatability compared to metal ceramic crowns. The improved biocompatability may be due to relatively non-oxidising alloy that is used. Juntavee et al have reported shear bond strength values similar to that of metal ceramic crowns.8

The biocomatability of titanium makes it a very desirable material for restorations. Computer Aided Design - Computer Aided Manufacture (CAD-CAM) technology is used in the laboratory (as opposed to scanning the tooth at the chairside) so that the clinician only needs to supply a conventional impression. A die made from this impression is scanned by the local laboratory and transmitted to a central laboratory in Sweden via a modem for the machining of the core. The external contours of the individual titanium cores for Procera bridges are milled and graphite rods create the fitting surface by a spark erosion process. Individual components of the bridge are then welded by laser before the addition of special porcelains to veneer on to the outer surface. In this way the application of the CAD-CAM technology, coupled with traditional spark erosion, is said to enable the production of accurately fitting titanium based restorations, whilst eliminating the need for costly and technically difficult casting procedures. The deficiencies of this system appear to be those inherent with processing titanium at elevated temperatures. The low fusing ceramics alleviate this problem to a certain extent, but do not 9

Metal free ceramics can be achieved in various ways. The conventional technique of "hydroplastic forms" whereby the powder and the liquid are mixed and fired several times still has a place. In fact, many of the newer techniques only produce the cores in a different way and the surface porcelain is still added in the conventional way. The newer techniques include thermal spraying, castable ceramics, pressable, infused and machinable ceramics. These are considered in more detail below.

Due to the increased leucite content, these porcelain have a higher compressive strength (146 MPa) compared to conventional feldspathic porcelain. As would be expected, in vitro studies have shown a greater potential for wear of the opposing tooth. A special semi-permeable die material is necessary for the processing but no other special laboratory

It is claimed that this reinforced ceramic has a refractive index of the surrounding glass matrix virtually identical to that of the leucite crystals. This is thought to result in better aesthetics as it enhances the natural look of

This is a dispersion-strengthened dental porcelain il which over 50% alumina crystals are employed as a reinforcing phase. The volume of the reinforcing phase is increased by means of a specific particle size distribution without sacrificing the aesthetics of the restoration or the ease 16

The increased strength of this material is attributed

Ducera MC is a high leucite containing core material which is used on a refractory die and baked at 9300 C. This is then layered with Ducera LFC, discussed below, which

This material must not be confused with the third type of Duceragold which is a ceramic layered onto a yellow" gold alloy. Duceragold is a 2-phased hydrothermal bonding ceramic. The homogeneity of Ducergold lies between Ducera LFC and Ducera MC.

Techceram, a British development, uses a thin (0.1-1mm) alumina core base produced by thermal spray technique. This results in a very dense core (of 80-90 %) which is then subjected to sintering to 11700 C. The surface is then constructed using the conventional porcelain build up technique with specifically developed porcelains. The inner fitting surface has microscopic roughness conducive to bonding and according to the manufacturers does not

Dicor is a tetrasilicic micaglass ceramic. As the name suggests it is the product of a marriage between Dentsply International (D1) and Corning ware New York (COR). The material is translucent and is claimed to have similar wear properties to that of the tooth. The laboratory technique required is similar to that of producing a crown

Surface glaze and colourants are necessary to reproduce the colour. Unfortunately the wear of the glaze poses problems. Hence Dicor Plus- feldspathic porcelain is recommended on the surface after cutting back the surface layer. This unfortunately negates the alleged beneficial wear characteristics of the core material. Furthermore, although the flexural strengths yielded values of 240 MPa compared to 116 MPa for Alumina reinforced core porcelain, the force required to break DICOR crowns is not significantly different to the latter.8 The core can be etched for bonding to tooth structure. However, theoretically such treatments can affect the strength of the materials, either by weakening the ceramic or by enlarging the surface flaws. However, a recent study by Yen et al by using ammonium bifluoride etchant showed no significant change in the strength.10

Empress (Ivoclar Vivadent) and Optec OPC (Jeneric/Pentron) utilises a technique where by a wax pattern of the proposed restoration is invested in a phosphate-bonded material. Following the burnout procedure, this leucite reinforced material is pressed into the mould using a special furnace (Figure 10) Final shading of the restoration is done by surface stains or by cutting back to apply Empress leucite reinforced porcelain in powder and slurry form depending on the aesthetic requirements (Figure 11). The core material is shaded, translucent and etchable for bonding to the tooth. Flexural strength of the material ranges from 126-165 MPa. These materials are suitable for individual crowns. It is proposed that the marginal fit of these restorations

More recendy IPS Empress 2 layering ceramic has been developed with flexural strength greater than 350 MPa which is suitable for 3 unit bridges up to second premolar as the final retainer. This material is quite different to the original Empress. Empress 2 consists of lithium disilicate glass ceramic as framework material (Figure 12) which is then coated with sintered glass ceramic. Their crystalline structure consists of only apatite crystals (fluoroapatite) unlike the conventional layering materials whose crystalline phase consists of leucite. The antagonist abrasion is claimed to be superior due to the apatite crystalS.11

In-Ceram: The core is formed from slurries of the fine alumina powder and water ("slip") and is applied to an absorbent refractory matrix, dried and lightly sintered to produce a porous core (Figure 13). The residual pores are then infused with molten glass by capillary action- hence the name In-Ceram (Figure 14). In-Ceram is now generally considered to be stronger than conventional porcelains.10 The resultant structure is the most efficient strengthening technique and gives a flexural strength value of up to 450 MPa. Unfortunately, the high degree of the alumina content makes it difficult to etch with hydrofluoric acid for bonding to tooth structure. The restoration can be bonded with Panavia 21TC after sandblasting. It is also

In-Ceram Spinel: This modification substitutes magnesium aluminosilicate for the aluminium oxide to provide for better translucency. It also avoids the yellow opacity typical of the In-Ceram. The yellow opacity may hinder the reproduction of the grey shades (e.g. Vita C and D). The abrasiveness of this material is the same as that of conventional feldspathic porcelains.

In-Ceram Zirconia: Compared with In-Ceram Alumina, this AL2 O3-ZrO2 ceramic material has improved mechanical characteristics. Due to its increased opacity, however, there are aesthetic limitations. It may be a suitable material for posterior bridges and posts and cores. As this Zirconia technique is still at its developmental stages, it is not yet available for extensive clinical study and application.

CAD CAM - Computer assisted design and computer assisted manufacturing systems are available using various techniques.

The Cerec System (Siemens) is the longest established CAD CAM system. In this method the preparation is scanned and the restoration milled from a block of ceramic material. Cerec have now introduced finer grained porcelain blocks to reduce opposing tooth wear as well as a wider range of tooth shades. They have also converted to an electric turbine to give better cutting control. Despite these improvements Siervo et al (1994) have shown that the marginal gap is two or three times at approximal margins and occlusal interfaces compared to Celay or sintered inlays.13 The inlay can be characterised with surface stains.

The original system used a pre-formed porcelain block similar to above system except that the diamond cutting wheel is steered by a pantographic arm with an attached probe which is guided by a preformed acrylic or wax pattern. The technique is similar to the established key cutting principle in industry. The modified technique uses an In-Ceram block manufactured for the purpose to produce a porous structure. The latter is then infused with glass

These are all ceramic individual restorations and comprise o f a densely sintered alumina core. A die is first created by a computer controlled milling process. Aluminium oxide is compacted onto the die to form the inner surface. The outer coping is then milled before the sintering is carried out. Feldspathic porcelain is added to complete the anatomic form and final appearance. This material is not indicated for inlays, onlays or veneers at the present time.

It can be seen that vast majority of the systems still rely on the feldspathic porcelains to complete the outer layer of the crowns. This is true of Dicor, Procera, Inceram, Empress (but not Empress 2). Posterior Dicor and Empress. Restorations could, in theory, be completed and simply stained without the need to layer with feldspathic porcelains if one is able to compromise the colour match slightly and accept the wear of the glaze in the long term. The newer layering or veneer porcelains are discussed below. It should be noted that manufacturers insist that in order to use these porcelains, the recommended core material for the system be used.

This is relatively new porcelain referred to as a "hydrothermal low fusing ceramic" (LFC). It is composed of an amorphous glass containing hydroxyl ions. It is claimed to have higher flexural strengths, greater fracture resistance and lower hardness than feldspathic porcelain (hence less abrasion). The inner core for the crowns is made from Duceram Metal Cerarnic- a leucite containing porcelain placed on a refractory dye and baked at 9300C. The Duceram LFC on the surface is subsequently baked at 6600C and can be surface characterised. There are no clinical studies substantiating these claims but in theory the material sounds promising. It has been suggested that the material is "self healing" as the potential cracks self-repair within the material. The wear rate is similar to that of the natural tooth. There are also some reports that the polishing of the surface with rubber wheels (e.g. Brassler polishing wheels) generates enough heat to "heal" the micro-cracks thus reducing the potential for crack

This is also a low fusing ceramic which can be used with many high-gold alloys as well. In addition to the standard shades, it is available in two new shades AO and BO to

LFCs do not etch very well and therefore cannot be used alone for bonded restorations. For this application, a thin coping of conventional porcelain must first be fired.

This porcelain system is designed to veneer specially fabricated yellow gold metal sub-structure made by the same manufacturers. It is claimed to have better wear characteristics due to reduced size of leucite crystals and the more homogeneous material structure which is more transparent.3 Furthermore it is claimed that "healing" hydroxyl layer in oral situation leads to strength increase as with Duceram LFC (low fusing ceramic) discussed above.

The crystalline structure consists of only apatit crystals (fluoroapatite) unlike the conventional layerin materials whose crystalline phase consists of leucite. From a materials point of view, it is quite different from the conventional IPS Empress layering materials, whOse crystalline phase consists of leucite. It is thought

The choice of the ceramic system is dictated by the presenting clinical situation.